Readers' Tips4

Our readers offer their own shop-tested tips for solving some of the most common woodworking problems.

Subscribe to ShopNotes magazine

Our readers offer their own shop-tested tips for solving some of the most common woodworking problems.

Made of highly figured walnut and brass, this torpedo level has the look and feel of a traditional hand tool. With a unique, built-in adjustment system, you can calibrate the level quickly and accurately.

Building a number of raised panel doors? You can use a special set of router bits to make the frame and the raised panel quickly and easily.

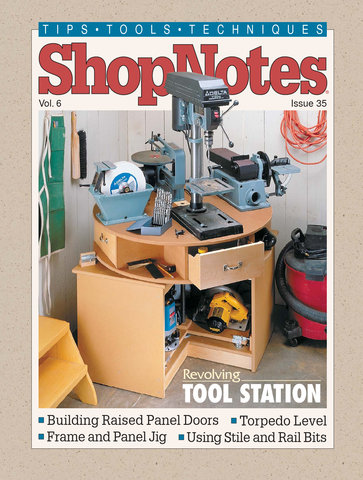

Just give the circular platform on top of this station a spin to position the tool you want to use right in front of you. A rotating turntable in the base provides easy access to your portable power tools as well.

A matched set of stile and rail bits and a router table. That's all it takes to cut the joinery and create the decorative profile on the frame of a raised panel door.

Use these tips from the guys in our shop to get professional-looking results on the project in this issue.

This shop-built jig solves the biggest problem of gluing up a frame and panel door -- keeping the door perfectly flat. The secret is a pair of cams that apply clamping pressure directly in line with the frame.