Readers' Tips4

Shop-tested tips to solve common woodworking problems.

Subscribe to ShopNotes magazine

Shop-tested tips to solve common woodworking problems.

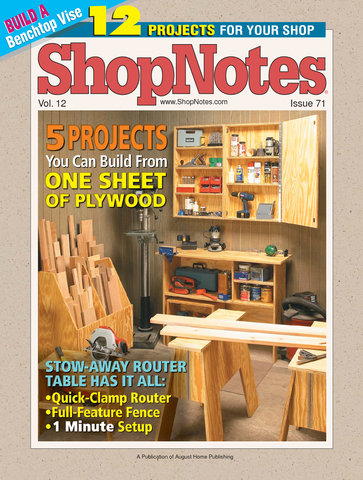

This space-saving shop essential has features some bigger router tables only dream about. It stows away when you don't need it and mounts to your workbench in less than a minute.

Cutting small box joints is one thing, but cutting them with fingers 2" long requires a little different technique. We show you how to do it with our step-by-step instructions.

Round stock, carvings, odd shapes -- this benchtop vise can handle it all. We've designed it with a variety of jaw faces and updated a classic design to meet today's needs.

Do you dread the thought of moving, storing, or cutting a large, heavy sheet of plywood? Learn a few of the techniques we use to make working with plywood hassle-free.

It won't take a lot of time, effort, or material to outfit your shop with storage, worksurfaces, and several handy accessories. Each project can be built from a single sheet of plywood.

Block planes have been around for a long time. But we've found one that incorporates some new features and accessories that are sure to make it one of your favorite tools.

Glue doesn't keep forever. Here's what you need to know to determine if it's "too old to hold" on your next project.