Subscribe to ShopNotes magazine

Creating a rail and stile joint doesn't have to be a lot of work. We'll show you how with a slot-cutter bit and one fence setting.

Here's what you need to know to get the best results when you use plastic laminate on your projects, shop jigs, and fixtures.

Looking to get less tearout and smoother cuts with your jointer? A spiral cutterhead might be the answer you're looking for.

Spiral cutterheads, like those shown in the article on page 12 of ShopNotes No. 89, are a great way to upgrade your jointer. The Sunhill and Byrd Shelix cutterheads came from Sunhill Machinery. I ordered the Woodtek Staggered Cutterhead from Woodworker's Supply.

Shop-tested tips and techniques to solve your woodworking problems.

Upgrade your contractor's saw by building this custom workcenter. With a large worksurface, loads of storage, dust collection, and a handy built-in router table, you'll be able to handle any project. Plus, there's an optional table for extra outfeed support and even more storage.

Much of the hardware you'll need to build the table saw workcenter on page 16 of ShopNotes No. 89 can be found at your local hardware store or home improvement center. But there are a few items you'll need to order to be able to complete the project.

The corner levelers (31217) for the cabinet, spring hinges (28845) for the doors, and 16" Accuride drawer slides (32482) all came from Rockler.

The 5/16" x 2" star knobs (DK-685) for the router table fence as well as the drawer handles (DUH-50) were ordered from Reid Tool.

In order to complete the router table, you'll need a few other items. The phenolic router plate (147) came from Woodhaven. And I picked up the dust collection port (715115) at the Woodsmith Store. A router table dust collection port (35317) is also available from Rockler.

You'll also need a miter gauge track for the router table. The Rousseau (0048) miter gauge track came from Mike's Tools.

To give the top of the workcenter a nice finished edge, you'll need to install some T-molding. I ordered the 1-1/2" black T-molding (#6) from T-Molding.com. You can find contact information below.

Finish Information: The paint we used was Benjamin Moore Eggshell Aquavelvet 319/3B, Buckland Blue HC-151 and Eggshell Aquavelvet 319/3B Sandy Shores 948. The laminate was WilsonArt D90-60 North Sea.

Want a new look for your shop cabinets and projects? With just a little time and some scrap wood, you can make all the pulls you need.

The drawer pulls shown on page 28 of ShopNotes No. 89 are easy to make and can save you some money. But you might need a few pieces of hardware in order to mount them.

Screws and threaded inserts are available at hardware and woodworking stores. But when I'm not sure of the length of the screw I'll need, I use a segmented, breakaway screw (35535) from Rockler. The rib-type, press-in threaded inserts (5645) can be found at Woodhaven. The split-type threaded inserts are available at Woodworker's Supply.

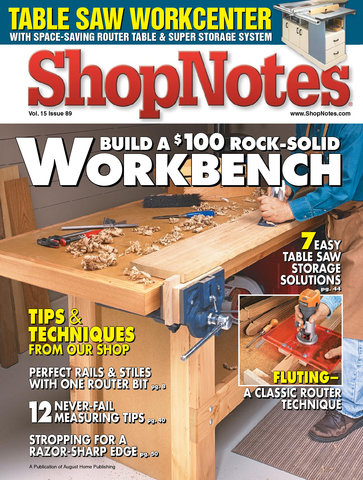

This workbench has it all -- a rock-solid base, large top, and it's inexpensive to make. All you need are a few sheets of MDF, some "two-by" stock, and a handful of hardware.

You can find almost all of the materials needed to build the workbench on page 30 of ShopNotes No. 89 at your local hardware store or lumberyard. But the vise I used to complete the project is a 9" quick-release wood vise (22876) from Rockler.

Finish Information: I used a stain mixture of 8 oz. of boiled linseed oil, 1 tsp. of Raw Sienna, 1 tsp. of Burnt Sienna, 1 tsp. of Van Dyke Brown, 3 tsp. Yellow Ochre and the finish was General Finishes One-Step. The project was built using Straight-grained Red Oak, Riftsawn Red Oak/MDF core Plywood.

Adding flutes is a great way to dress up a project. This shop-made jig makes it easy to rout consistent flutes quickly.

You can find the hardware you'll need to build the router fluting jig on page 36 of ShopNotes No. 89 at a local hardware store or home center. But you'll probably need to order a sheet of acrylic for the base plate. The 1/4"-thick, flourescent orange acrylic (86205) was ordered from United States Plastic. You'll find contact information below.

Measuring and marking is an essential skill for successfully building any project. Here are a dozen foolproof tips for doing it right.

Need more storage? You'd be surprised how easy it is to create some around your table saw.

With a molding head and just a few cutters, you can easily create a wide range of profiles.

A molding head and cutter set, like the one in the article on page 46 of ShopNotes No. 89, can add versatility to your table saw. The one featured is a molding head and cutter set (34-813) made by Delta. It includes a molding head, Allen wrench, and four sets of cutters. I ordered mine from Mike's Tools, but they're also available through Amazon.com and Woodworker's Supply. You'll find contact information below.

Woodworking in a cold shop isn't fun. Learn all you need to know about adding a little heat.