Table of Contents

Readers’ Tips4

Updates

-

Page 7: Illustration

Two of the arrows in the illustration are not pointing to the correct objects. The BASE arrow should point to the base piece of plywood, not to the hole. And the “HOLE FOR WALL HANGING” arrow should point to the hole, a little farther left than where it currently points.

All About Ogee Bits8

Learn the differences among ogee bits to

choose the right one for your next project.

The Low-Down on Lathe Chucks10

A 4-jaw chuck is a great upgrade for any

lathe. Here’s what to look for before you buy.

Sources

You can find a variety of 4-jaw

chucks at most woodworking

suppliers and online retailers.

The Easy Chuck is manufactured

by Easy Wood Tools.

Cabinet Hardware Solutions: Locks14

Keep items secure behind closed doors and

drawers with a simple cabinet lock.

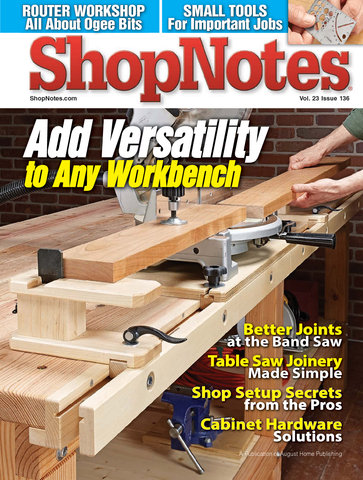

Add-On Workbench Rail System16

Every workbench needs simple ways to

secure tools and workpieces. This system

has a lot of great features, and you can easily

add it to any workbench.

Custom Block Plane22

There’s nothing like using a tool you build

yourself. This block plane features solid

double dovetail construction, an easy-to-adjust

iron, and a custom hardwood infill.

Updates

-

Page 26: Figure 3

In preparing the online extras for the infill block plane, we discovered some errors and decided to make adjustments to the sizing of the Lever Cap “C”. The distance from the front (lower) edge of the lever cap to the shoulder is now 1 instead of 7/8. The distance from the shoulder to the top of the lever cap is now 1/2 instead of 5/8. The concave radius on the lever cap is now 5/8 instead of 9/16.

Sources

For the steel-sided plane, we purchased

a 3"x17" billet of Damascus

steel from Alabama Damascus

Steel. The thickness should be

.14"-.175" thick. On the website,

you can select the specifi c pattern

you like for your plane.

Bridle Joints at the Band Saw30

Unlock the versatility of your band saw by

using it to cut joinery. Here’s how to get

accurate results right from the start when

cutting bridle joints.

Shop Short Cuts32

Check out our shop-tested tips and techniques for solving your woodworking problems.

Rotary Tool Milling Machine34

Get more from your rotary tool by turning it

into a pint-size milling machine. This low-cost,

shop-built tool builds in the accuracy you

need for small detail work.

Updates

-

Page 39: Main Illustration

The Fixed Jaw should have a dimension of (1" x 1 1/2" x 3 3/4").

-

Page 40: Figure 11

The length of the threaded rod is missing. The callout for that rod should read: 3/8"-16 x 9 3/4" LH Threaded Rod w/Thin Hex Nuts & Washers.

-

Page 36: Figure 1

The dimensions of the notch on the top edge of the Tool Platform are not given. The notch is 2" wide by 3 1/2" tall. All corners (inside and outside) are 1/4" radii.

-

Page 40: Figure 11

The z-axis gibb on the left side has a part 'T', it should be a 'U'.

5 Keys to Choosing a Bench Grinder42

Looking for a bench grinder? These five keys

will help you choose the right one.

Setup Secrets from a Pro44

This basement shop has a lot of great solutions

for getting more from any space.

Joinery Made Simple: Offset Tenons46

Cutting offset tenons at the table saw is easy

with a tenoning jig and these handy tips.

Small Tools for Important Jobs48

The right tool makes any task easier. These

pocket-size options are worth a look.

Q&A50