Readers' Tips4

Our readers offer their own shop-tested tips for solving some of the most common woodworking problems.

Subscribe to ShopNotes magazine

Our readers offer their own shop-tested tips for solving some of the most common woodworking problems.

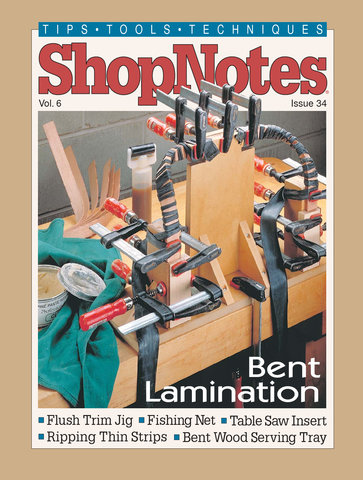

The curved sides and the bent wood handles of this serving tray are both made by gluing up thin strips of wood. But they provide two different bending challenges.

This shop-made insert for your table saw has a "zero-clearance" opening for the blade that provides a safe way to rip thin strips. And it reduces chipout as well.

Two different methods for ripping thin strips of wood to a uniform thickness -- just what you need to ensure success when making a bent lamination project.

Trimming solid wood edging flush with the surface of a workpiece is easy with this flush trim jig. All you need is a hand-held router and a straight bit. There's also an optional edge guide for routing rabbets.

What's the secret to bending wood into a graceful, flowing curve? It's the details. We show you how to "read" the grain of the wood strips used to make a bent lamination, design the bending jigs, and glue up the strips.

The bent wood frame of this fishing net is accented by a walnut strip and handle that are sandwiched between four maple strips. Just string the net on the frame and head off to your favorite fishin' hole.

These tips from the guys in our shop make it easy to get professional-looking results on the projects in this issue.