Table of Contents

Readers' Tips4

Our readers offer their own shop-tested tips dealing with some of the most common woodworking problems.

Dado Blade Storage Case6

The "hanging files" in this storage case hold the chippers and blades of a stacked dado set. This provides easy access to the individual pieces and protects them from damage.

Restoring a Bench Plane10

Turn an old rusty bench plane into a hard-working tool that looks great too. Also, we include step-by-step instructions on making a new handle or front knob.

Tuning Up a Bench Plane14

A bench plane is a precision tool -- when it's tuned up properly. Here are some simple tips and techniques to help you get the most out of your bench plane.

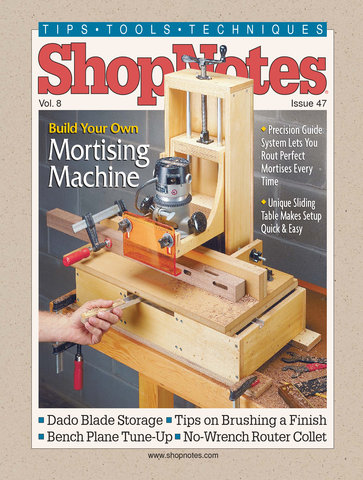

Mortising Machine16

This shop-built mortising machine lets you rout perfect mortises every time. With a router carriage that moves up and down and a table that slides in two directions, you can set up the machine and cut a mortise in less than a minute.

Updates

-

Page 18: Figure 1

The length of the notch in the front (A) is printed as 7" but should be 6 3/4". The notch is located 8 5/8" from the left end, not 8 1/2" as shown in original article.

-

Page 20: Instructions (assembly note needed)

The crank has a flange that mounts to the upper guide block of the carriage (fig. 11). Before installing the crank, you'll need to drill a hole in each corner of the flange for the #6 x 1" roundhead screws that hold it in place.

-

Page 22: Figure 12

The groove for the lower runner is located 3 5/8" from the front edge of the lower table, not 6" as originally printed.

-

Page 22: Instructions (assembly note needed)

The strips of phenolic for the runners are slightly wider than necessary. This will make it easy to get the runners to slide smoothly in the aluminum track. Just attach a piece of sandpaper to a flat surface (like the top of a table saw). Then sand the edges of the phenolic strips until the runner slips into the channel. Using a scrap of wood as a "fence" will help keep the edge of the phenolic strips square.

-

Page 22: Instructions (assembly note needed)

The bearing that fits into the aluminum channel (see fig. 11, detail a) for the handle is specified at an exact diameter of 3/4". Manufacturing tolerances on the aluminum channel may result in an inside channel dimension that is slightly less than 3/4". To allow the bearing to slip into the top of the channel, lightly sand a small section (2" long) on each side of the interior walls. Note: This area is centered 4 1/4" from the end of the handle.

-

Page 23: Figure 14

The groove that is cut in the upper table to accept the fence face (S) should be located 6" from the front edge of the upper table, not 6 1/4" as printed.

Brush Basics26

One of the secrets to getting a smooth, even finish is the quality of the brush. We offer practical suggestions on selecting brushes, applying a finish, and some clean-up tips.

Tool Talk30

In this issue, we take a look at an innovative new router collet that doesn't require a wrench to tighten the bit.

Scenes from the Shop32